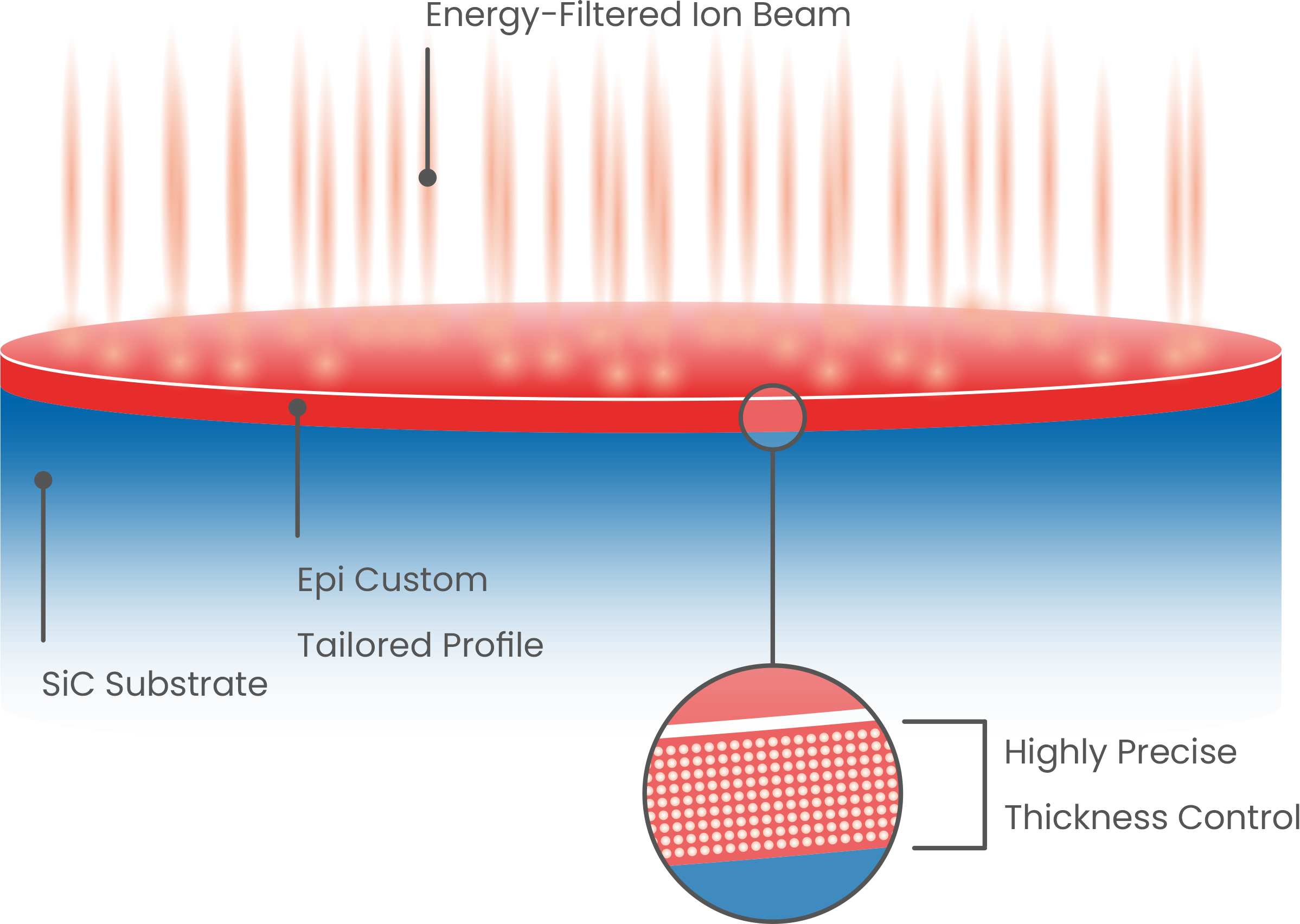

SiC Epi Doping

A highly precise technology

The Energy-Filter technology guarantees high precision epi layer doping and improved thickness uniformity. Chip manufacturers are guaranteed higher device yield and quality alongside substantially improved cost efficiency.

SiC Diode Drift Zone

Doping with highly augmented accuracy

Our cutting-edge Energy-Filter technology provides exceptional n-type drift zone doping for 600V-1200V SiC power devices.

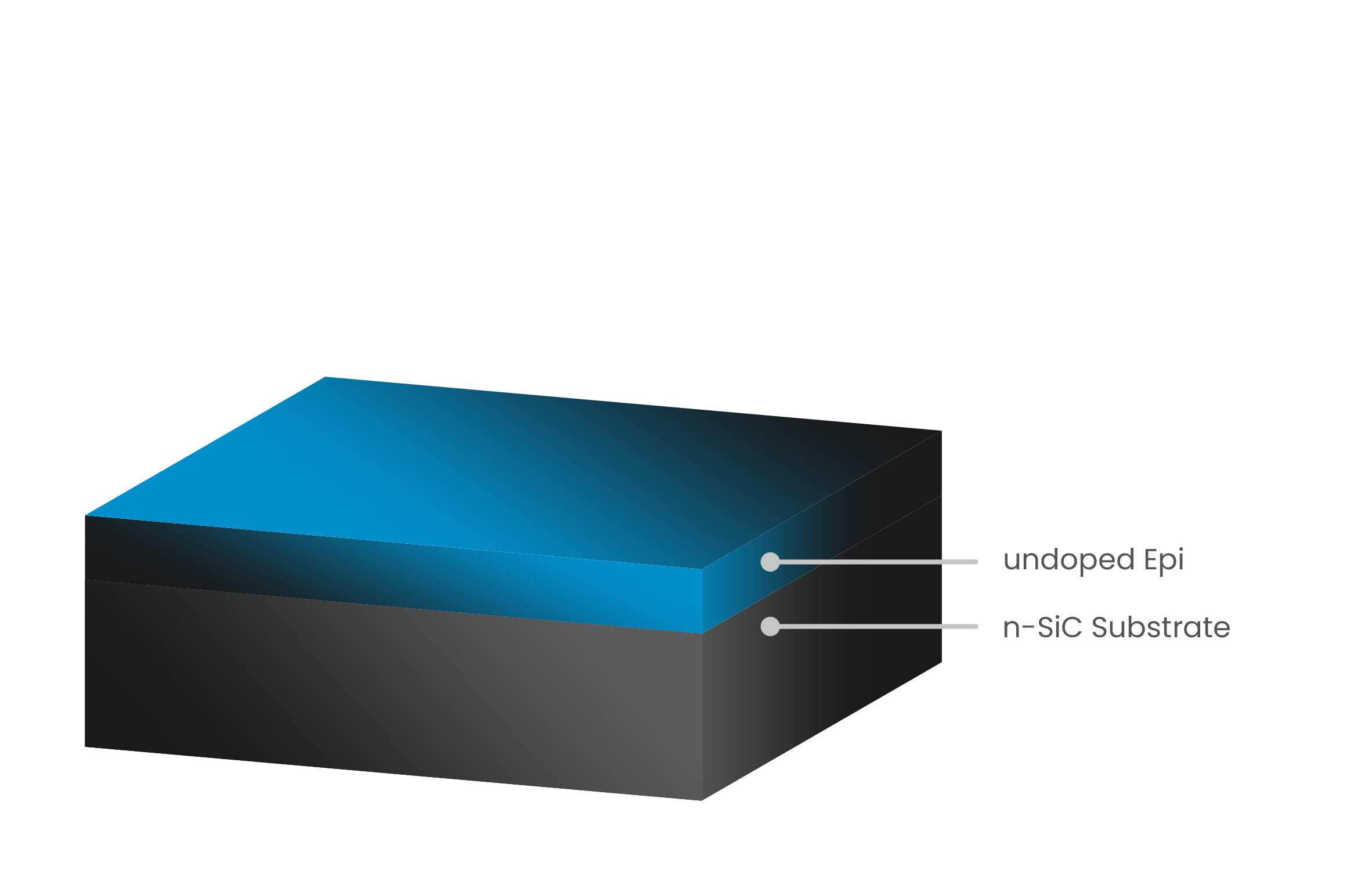

We recommend using undoped epitaxial layer formation followed by the Energy-Filter process to manufacture n-type drift zones. This method will help to realize previoulsy unattained levels of doping uniformity.

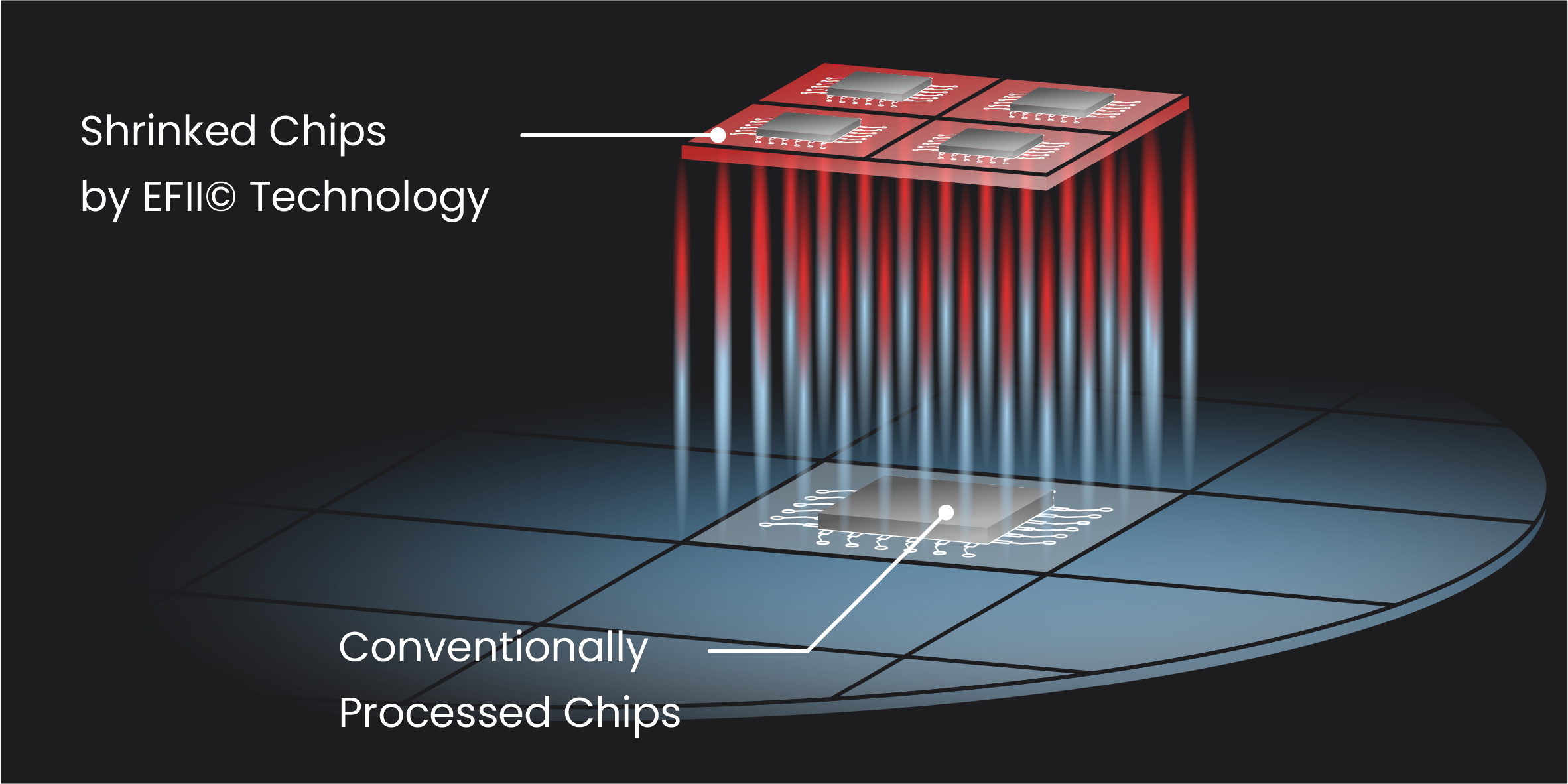

Benefits

mi2-factory’s blanket Nitrogen-EFII© process results in drift-zone doping with highly augmented accuracy:

direct cost benefit for MPS diodes and MOSFETs

potential chip shrink of over 30% for 1200V MPS diodes

tighter distributions of forward voltage drop and breakdown voltage

Applications

more than

30%

chip shrink potential

less than

3%

depth range variation

less than

3%

doping inhomogeneity

Results from packaged chip data

Our test vehicle – the 650V SiC MPS diode from Infineon Technologies – has provided robust and compelling proof of the Energy-Filter technology’s succesful translation to and suitability for commercial settings and applications. The IQR/median value of packaged diodes is much smaller for chips processed with EFII© technology than for conventional chips. Forward characteristics up to 10x 12A*.

*data from joint project between Infineon Technologies AG and mi2-factory GmbH, 2015

Alternative highly homogenous drift layer doping for 650V SiC devices (R. Rupp et al, Materials Science Forum, ISSN: 1662-9760 Vol. 858, pp 531-534)

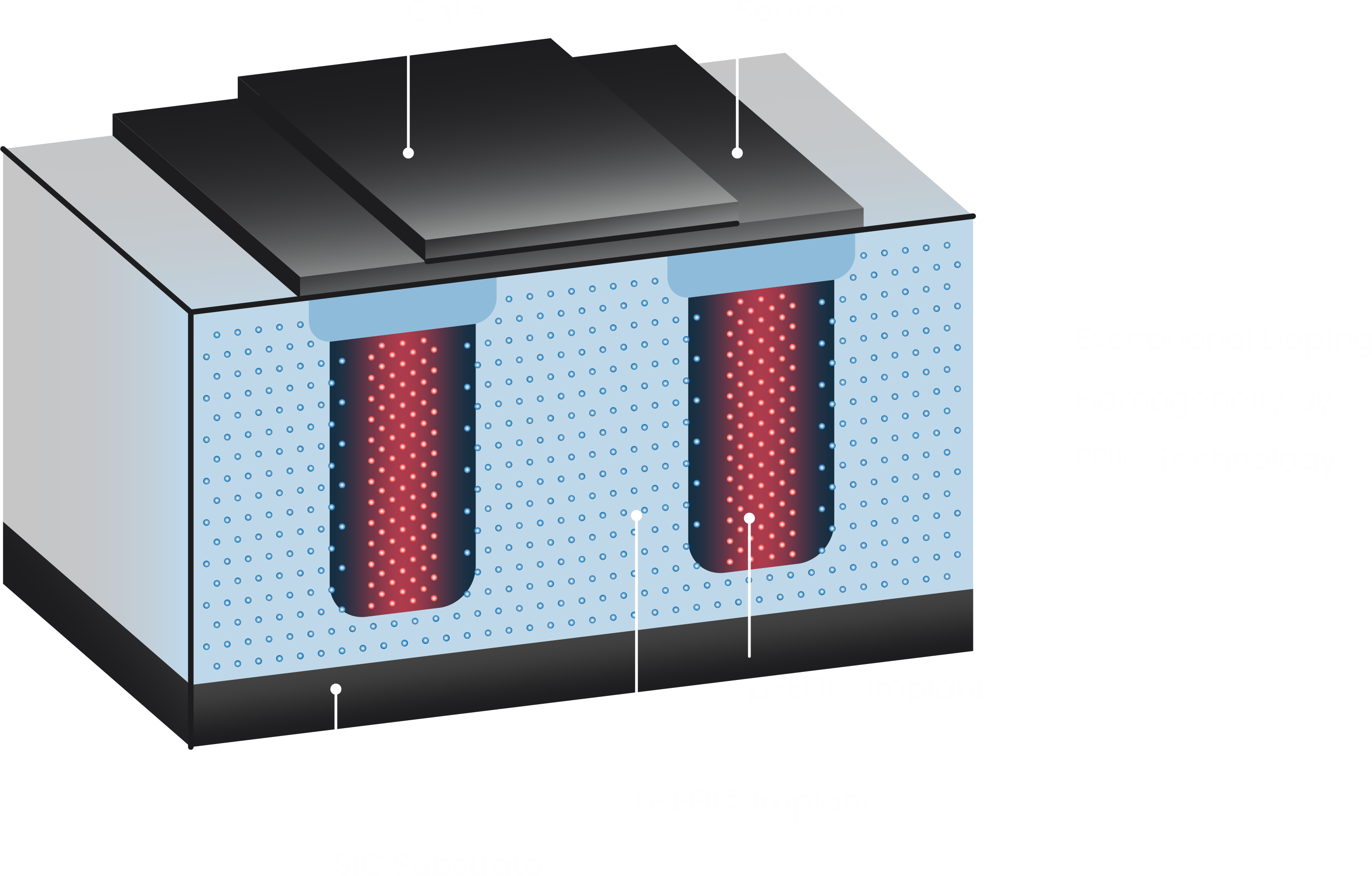

SiC Superjunction MOSFET

A powerful technology for your powerful MOSFETs

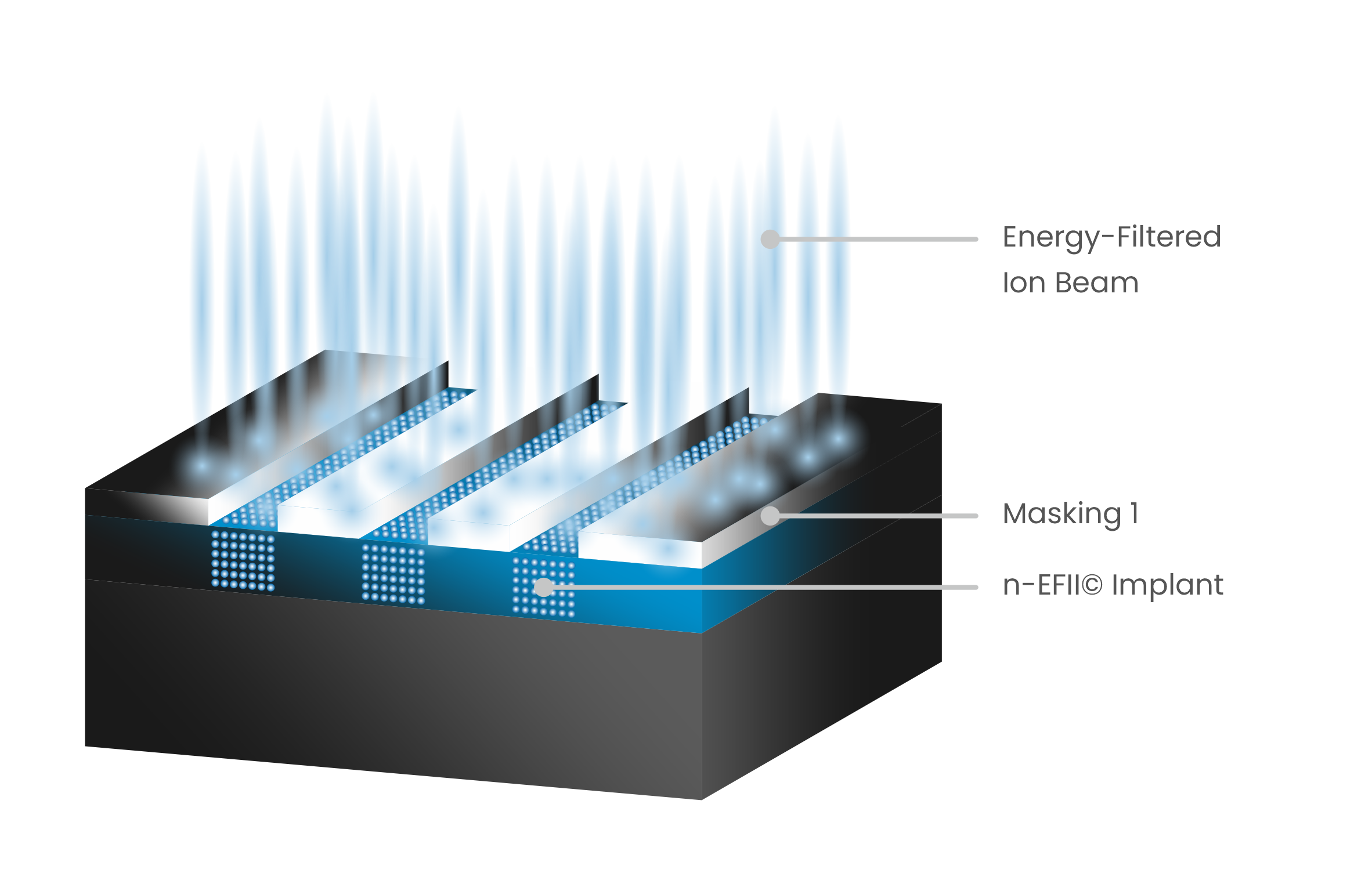

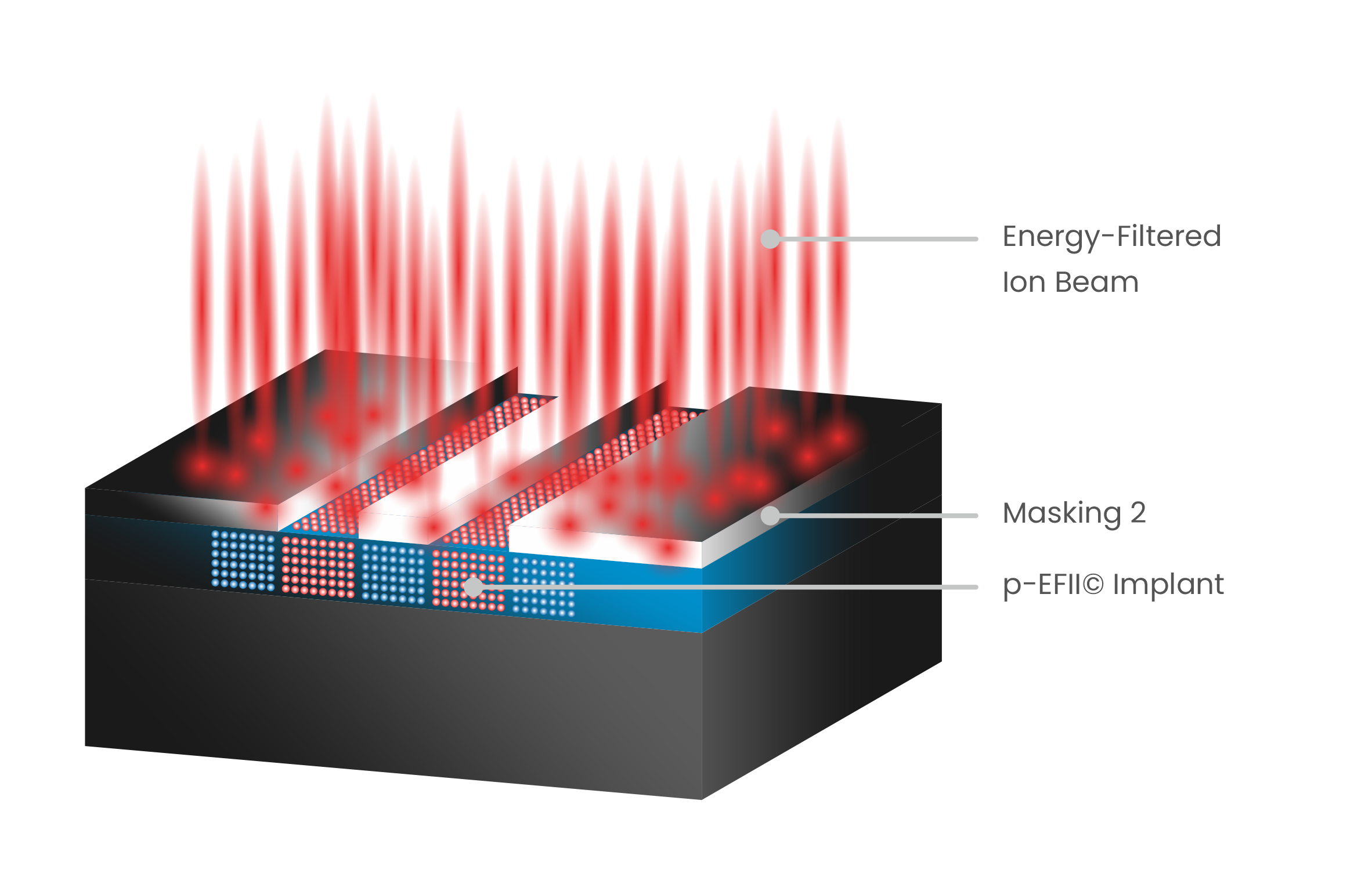

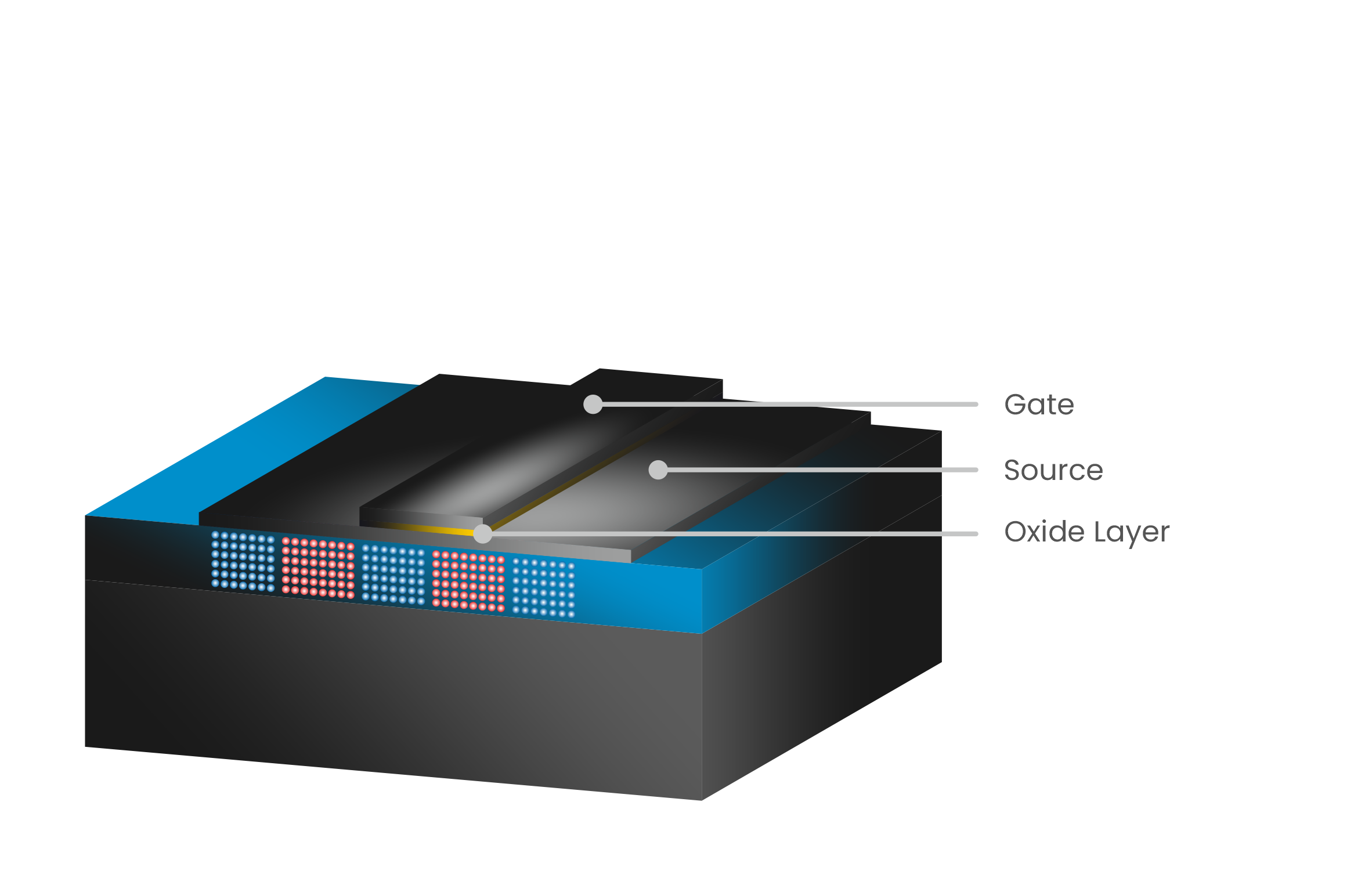

1.2kV SiC superjunction (SJ) MOSFETs are superior in cost-performance compared to conventional MOSFETs. But how to manufacture a SJ structure in SiC? Our approach: multiepitaxy with masked EFII© p- and n-implant.

Approach

Our approach of multiepitaxy with masked EFII© p- and n-implants enables cost-effective manufacturing of superjunction structures in silicon carbide. Our technology provides specialized implantation and undoped epi regrowth.

Applications

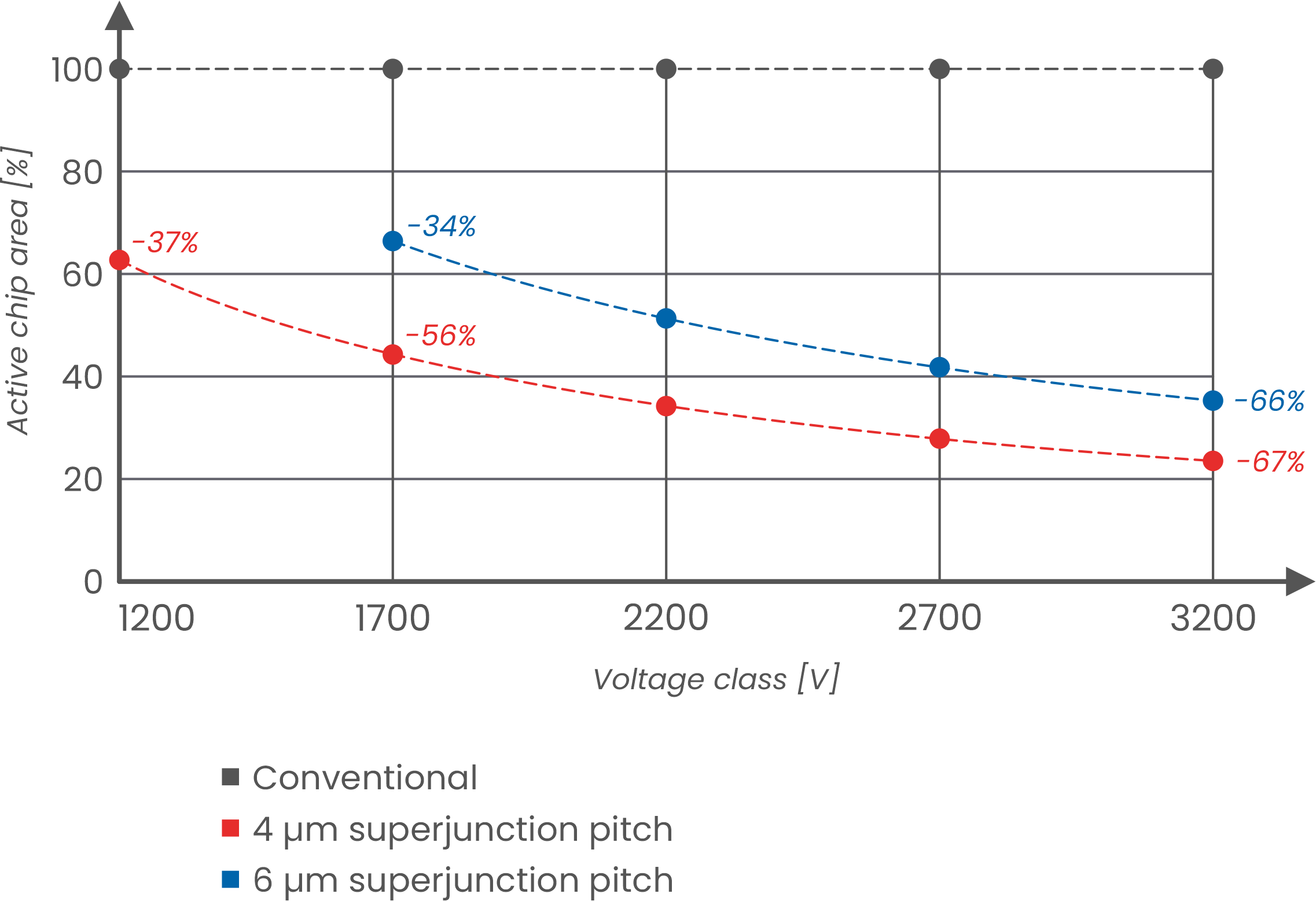

Active chip area reduction

In the graph below, the active chip area reduction afforded by SiC Superjunction MOSFETs relative to conventional SiC MOSFETs is visualized.