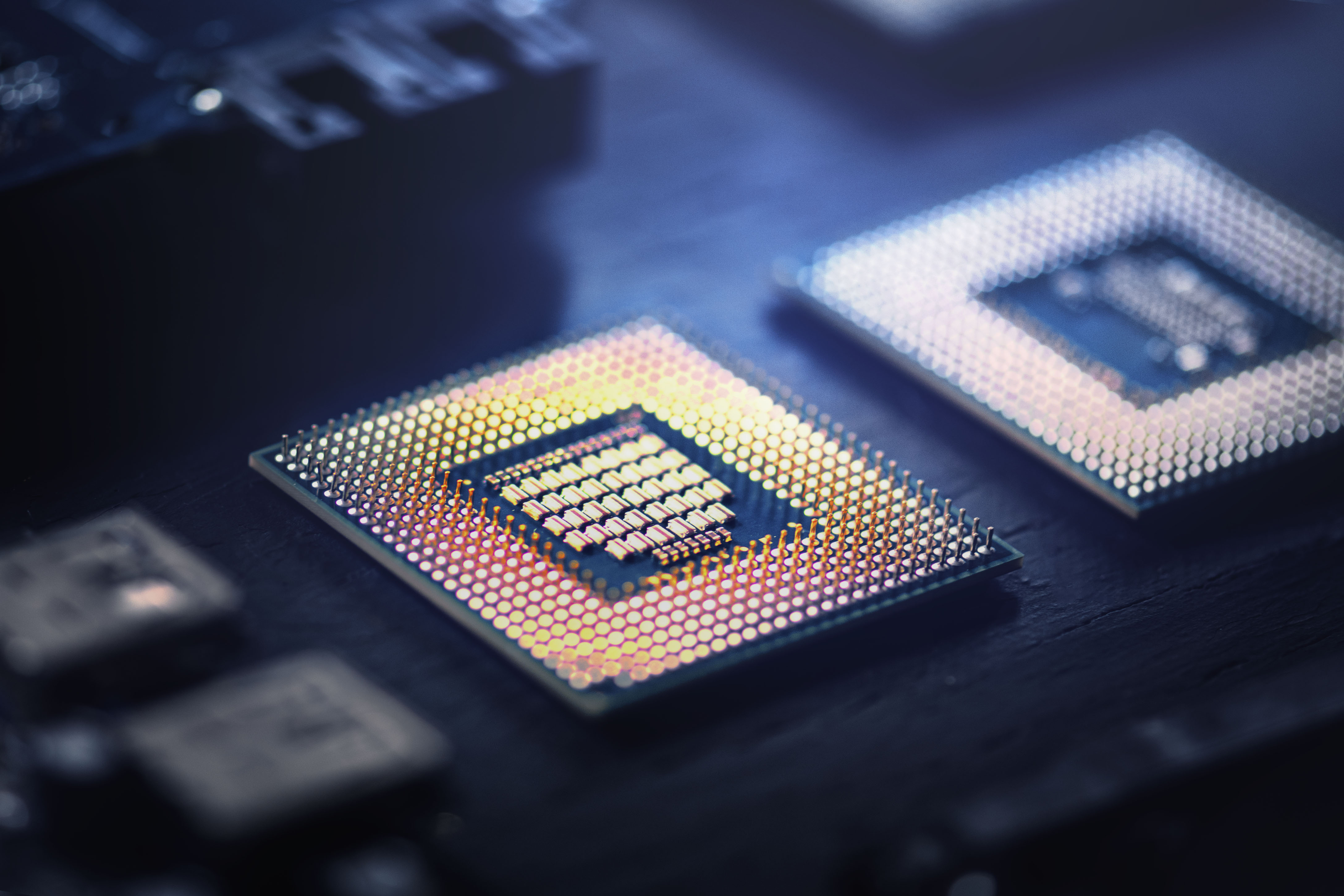

“The Federal Ministry of Economic Affairs and Climate Action (BMWK) supports Important Projects of Common European Interest (IPCEI) in the fields of microelectronics and communication technologies. The funding supports developments of future-oriented, innovative microelectronics and communication technologies up to market maturity. The developments are intended to complete the European value chain and thus contribute to European technological sovereignty. Energy-efficient technologies and processes advance climate protection.”

“Funded by the European Union – NextGenerationEU. The views and opinions expressed are solely those of the author(s) and do not necessarily reflect the views of the European Union or the European Commission. Neither the European Union nor the European Commission can be held responsible for them.“